- Home

- Discover

- Your applications

- Case studies

- XIMEA cameras feature prominently at Robotex 2012

To help train the next generation of engineers, XIMEA recently supplied the top university teams at Estonia’s annual robotic competition, ROBOTEX, with XIMEA industrial cameras for machine vision robotic guidance.

Using XIMEA's Best CURRERA Application teams acquired CURRERA-R smart PC cameras and xiQ USB3 Vision cameras for the three-day robotic competition.

ROBOTEX tests each team’s ability to design a robot that can accomplish several tasks, from following a line to autonomous soccer.

Apparently having good cameras provides you with a competitive edge not only in industrial machine vision, but also in robot, because all three finalists used XIMEA cameras to achieve their goal.

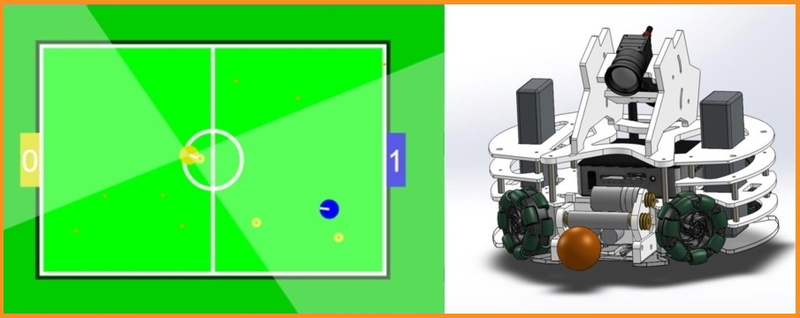

The ROBOTEX autonomous Robot Soccer rules are a hybrid between the small- and middle-size league rules of the largest robotic soccer competition, ROBOCUP.

Robotex competition is always the high-point of the three day event.

The pro-league robots use computer vision to find the footballs (orange golf balls) on a field that 4.6m x 3.1m field with a pair of 0.7m-wide goals.

There are a total of 11 balls on the field, and the winning robot has to get all 11 balls into the opposing team’s goal.

The one to do it fastest in two rounds wins and moves to the next round of the tournament.

Each game consists of a maximum 3 rounds with each round lasting 90 seconds.

“I just wanted to say thank you to XIMEA for the CURRERA-R camera and your support, which made this win possible,” Tammepõld said.

Images of the two goals were fed into Monte-Carlo Localization algorithm (particle filter) for navigation, while the a solenoid coil gun to ‘kick’ the ball into the goal.

“We use the RAW RGB images from the cameras at half the supported resolution (640x512), which we can process at about 45 frames per second (fps) from the two cameras. The image segmentation is made in YUYV color space,” explained Priit Kallas, of Tartu University.

“We’re doing the conversion from RAW to YUYV using. Quality and performance of the Ximea cameras helped us build a very competitive robot with good vision capable of chasing after small golf-balls from across the field and we’re very thankful for the support.”

The use of smart camera with Intel Atom processor eliminated the need for any external PC.

The main task for CURRERA-R was object recognition.

Custom software in robot was able to detect balls, goals and field borders.

Thanks to XIMEA's fast image acquisition data path, Neve3 was able to image the field 60 times a second.

Depending on the types of objects to be detected, the recognition program was running at speeds up to 40 frames per second.

This kind of speed and the camera’s overall low latency gave Neve3 a very fast response time.

It is very important when driving towards a ball and at the same time making small corrections to hold the ball in the center of image.

The custom software was able to calculate the size and distance to different objects from image.

CURRERA-R smart camera was used also for other tasks than computer vision.

All of robots high level control was also implemented in CURRERA Smart camera which was connected through RS232 to microcontroller based on Atmel AVR.

This microcontroller was in charge of reading sensor values and controlling motors and solenoid.

High level program in CURRERA-R took the result of computer vision and sensor values from microcontroller and based on this information made decisions what actuator commands to send.

Neve members: Kristjan Mölder, Valdur Kaldvee, Erik Kaju, Laur Mõtus

Author of the pictures : Jelena Pljonkina.

Links: Photos

Videos:

http://www.youtube.com/watch?v=ST91mmgsvDY&feature=youtu.be&t=35m39s

http://www.youtube.com/watch?v=gkfyccqlAsI

Related articles

Latest articles

Accelerate edge intelligence with XIMEA’s ultra-low latency PCIe cameras. Stop by for live demos and tech deep-dives with our team at Booth #3231

Visit us at booth #1026

Visit XIMEA at booth #0A095 to get hands-on with cutting-edge camera tech built for flexible payloads, mapping, and more.

Join us at booth #3138!