- Home

- Discover

- Your applications

- Case studies

- Case study: The next step in carbon-neutral energy production

Future of carbon-neutral energy production

The Dutch Institute for Fundamental Energy Research (DIFFER) is currently developing a carbon neutral energy production through the means of nuclear fusion.This complex process requires a failsafe control system to oversee that the whole procedure is secure and smooth.

The multi-spectral imaging system called MANTIS is part of the structure and it utilizes the XIMEA multi-camera setup to help maintain a stable state.

The PCIe technology on which the solution is based enables data retrieval at virtually zero latency ensuring real time capabilities of the system.

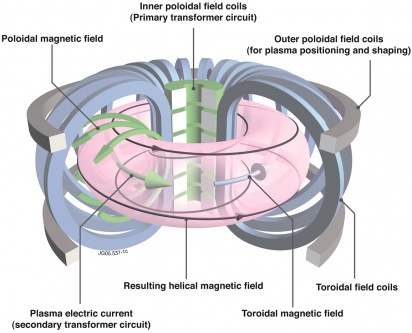

Description of Fusion

One of the challenges of the 21st century is the energy transition to a carbon-neutral economy.This could be achieved with solar and wind power. However, these renewable sources are dependent on seasonal changes.

To complement them and advance the transition from fossil fuel-based energy, a weather independent source of energy is needed.

Nuclear fusion offers a clean, sustainable and inexhaustible source of energy.

In short, Nuclear fusion is a process during which two light nuclei are fused together to form heavier elements while releasing energy.

It is the source of almost all energy here on earth: the sun runs on nuclear fusion, converting hydrogen into helium.

The conditions for nuclear fusion can be reproduced in a high temperature plasma reaching 150 million °Celsius.

This can be achieved in experimental nuclear fusion reactors called tokamaks - doughnut-shaped vacuum vessels that use magnetic fields allowing them to contain the hot fusion plasma.

Nuclear fusion reactor designs aim to sustain a plasma burn at 150 million °Celsius in their core. Thus, components facing the inner wall must endure operating temperatures of about 1500 °Celsius.

The principle challenge remaining is then to extract the heat energy (for power generation) without exposing sensitive components to either the high heat or particle flux generated by the plasma.

DIFFER institute and task

At the Dutch Institute for Fundamental Energy Research DIFFER, scientists and engineers work together to develop theoretical models, diagnostic instruments and advanced control systems to safely exhaust power from fusion plasmas.DIFFER's approach focuses on employing physics and control theory to spread the exhaust power over a wide area.

This can be achieved via a collection of atomic and molecular physics processes collectively called plasma detachment.

The challenge is to keep the processes in balance: excessive cooling in the plasma exhaust will disrupt the plasma core and decrease the efficiency of power production, while insufficient cooling will damage the plasma facing components.

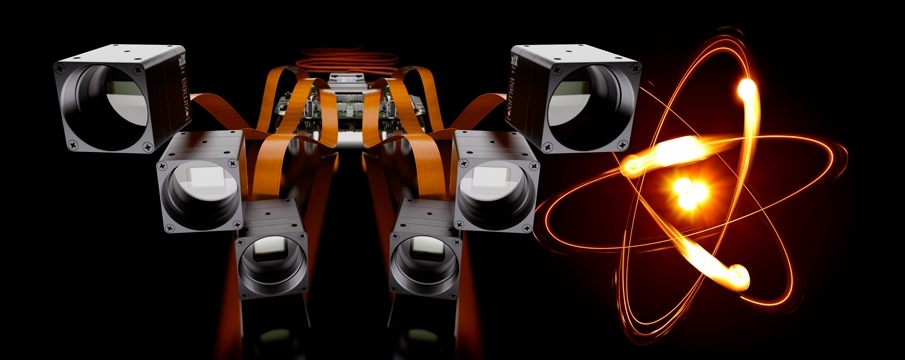

Setup with XIMEA cameras

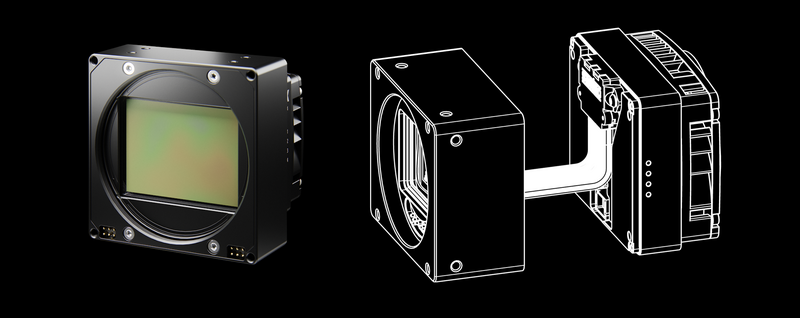

To achieve detachment, DIFFER collaborated with MIT and EPFL to develop a new diagnostic system called MANTIS, an advanced multispectral narrowband tokamak imaging system.The MANTIS is equipped with 10x XIMEA cameras from xiX line, simultaneously acquiring quantitative images of intensities of different spectroscopic emission lines.

This allows the researchers to follow different atomic and molecular processes simultaneously.

The images are then used in theoretical models to serve as an input to a model-based detachment controller which can modify the power exhaust in real-time.

The technical challenge of MANTIS is to simultaneously acquire and process images on 10 cameras. That is enabled by the Direct Memory Access (DMA) provided by the xiX camera models using PCIe interface technology.

Data delivery is provided at nearly no latency or CPU overhead, so the cores are free to process the incoming data streams.

MANTIS is much more than a multi-camera-system, it is also a part of the control system.

To achieve the control goals, the cameras must deliver real-time performance on the timescale of tens of microseconds and with as little latency as possible.

A single frame freeze could disrupt the balance between sufficient cooling and maximum plasma performance.

This is where the integration becomes difficult…

The optical cavity of MANTIS equipped with the xiX cameras

Overcoming the hurdles

The original XIMEA PCIe driver works on event-based synchronization, where a camera sends an event to the event queue for processing by the event handler.This method works best to minimize the power and CPU time used for the acquisition.

With an increasing number of events, however, the timing becomes more uncertain.

To counter that effect, the MANTIS team developed an extension for the XIMEA driver.

It uses XIMEA’s circular DMA buffers to predict where the next frame will be delivered.

It then polls on the last pixel of that frame until it is non-zero, meaning that the frame was just delivered to the DMA buffer.

This approach resulted in communication jitter reduction from ~1ms to less than 200 ns on 10 cameras simultaneously.

“I was shocked when I found out how well the cameras performed in our real-time application, and all of that with a simple change of synchronisation scheme.” — Artur Perek, MANTIS system developer.

Support from XIMEA

XIMEA’s team took the idea further by altering the XIMEA PCIe driver to enable metadata retrieval on the same time scales.These changes made the xiX cameras fully real-time capable for MANTIS and many other applications. This project uses MX031 camera model and XS12 switch.

Product in harsh environment

In addition to the spectacular real-time performance, the cameras also survived an entire experimental campaign in the nuclear fusion reactor of the Swiss Plasma Center, the Tokamak à Configuration Variable (TCV).During the campaign, the cameras were exposed to time varying magnetic fields, neutron, gamma and X-ray radiation. Following DIFFER experiences, other fusion research groups turned to XIMEA to purchase their cameras.

Related articles

Case studies

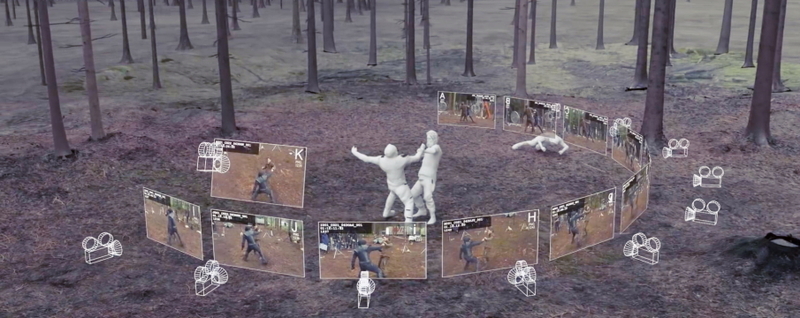

Volumetric capture technolgy enhanced through a multi camera system with more than 100 camera units

Read article

Case studies

Automation of animal observation and training through combining vision and deep-learning

Read article

Case studies

Aurox used specially designed sCMOS cameras from XIMEA to develop an all-in-one microscope

Read article

Latest articles

Exhibitions

High-performance BSI sensors, high-speed PCIe interfaces, and a range of other exciting camera innovations.

Join us at booth #3138!

Read article

Join us at booth #3138!

Exhibitions

Visit XIMEA at booth #A3.312! Explore our updated USB3 and PCIe camera portfolio: super small, incredibly fast, and high-resolution. Our team is ready to showcase them!

Read article

Product news

USB3 and PCIe cameras with 4th generation of Sony sensors like IMX545, IMX546, IMX547

Read article

Exhibitions

High performance BSI sensors, high speed PCIe interfaces and many more exciting camera innovations. Find us at booth #3674.

Read article